CAD Cutting

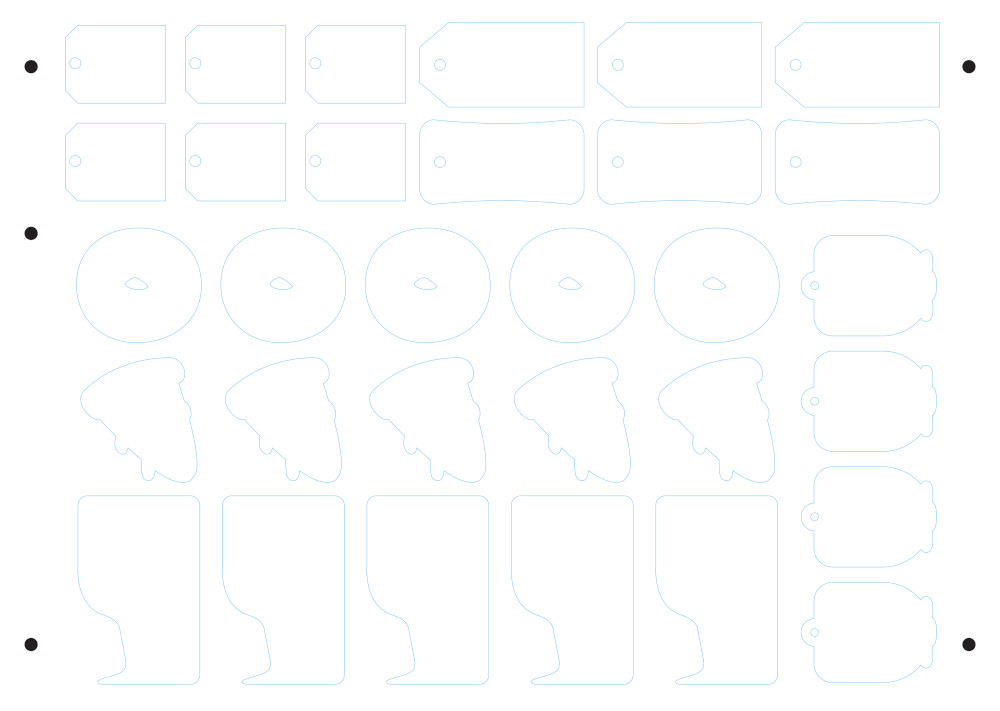

Create a shapely impression – any of our products can be CAD cut, making the finished shape anything you can dream up. Unlike die cutting, no forme is required – instead a computer slices your material one sheet at a time.

How it works

CAD Cutting uses a straight edged blade that cuts directly to material like a scalpel. This blade is great for making intricate cuts on materials such as papers, fluted boards and correx.

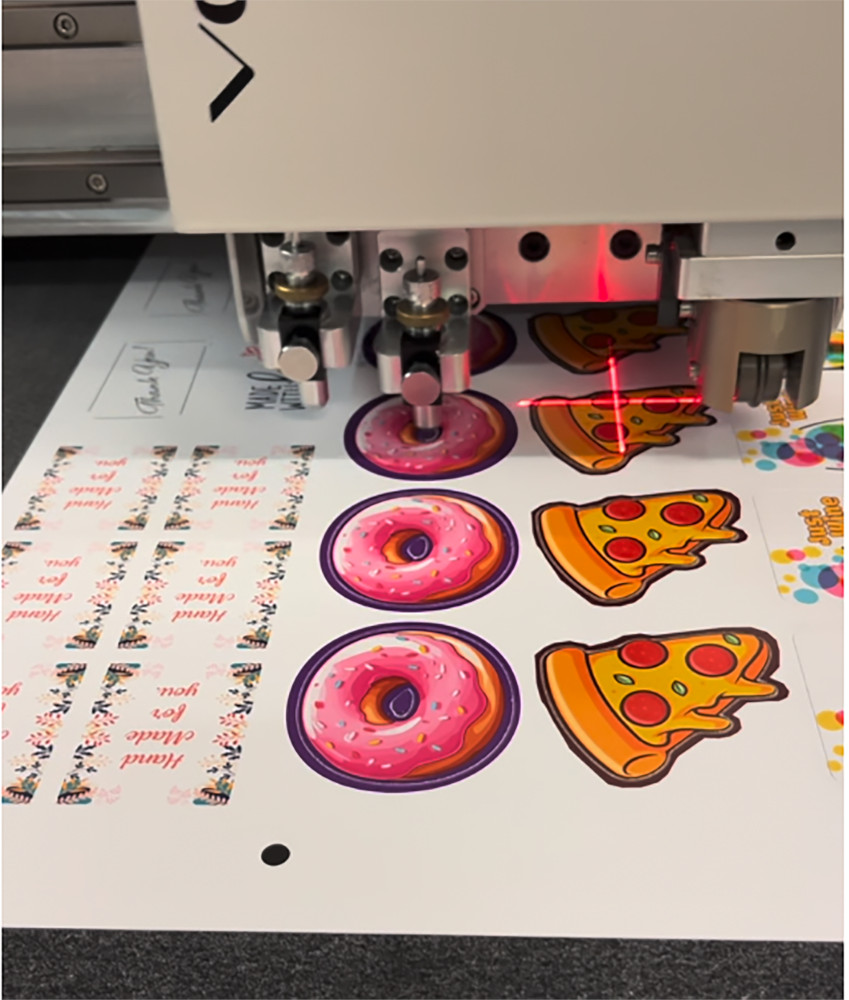

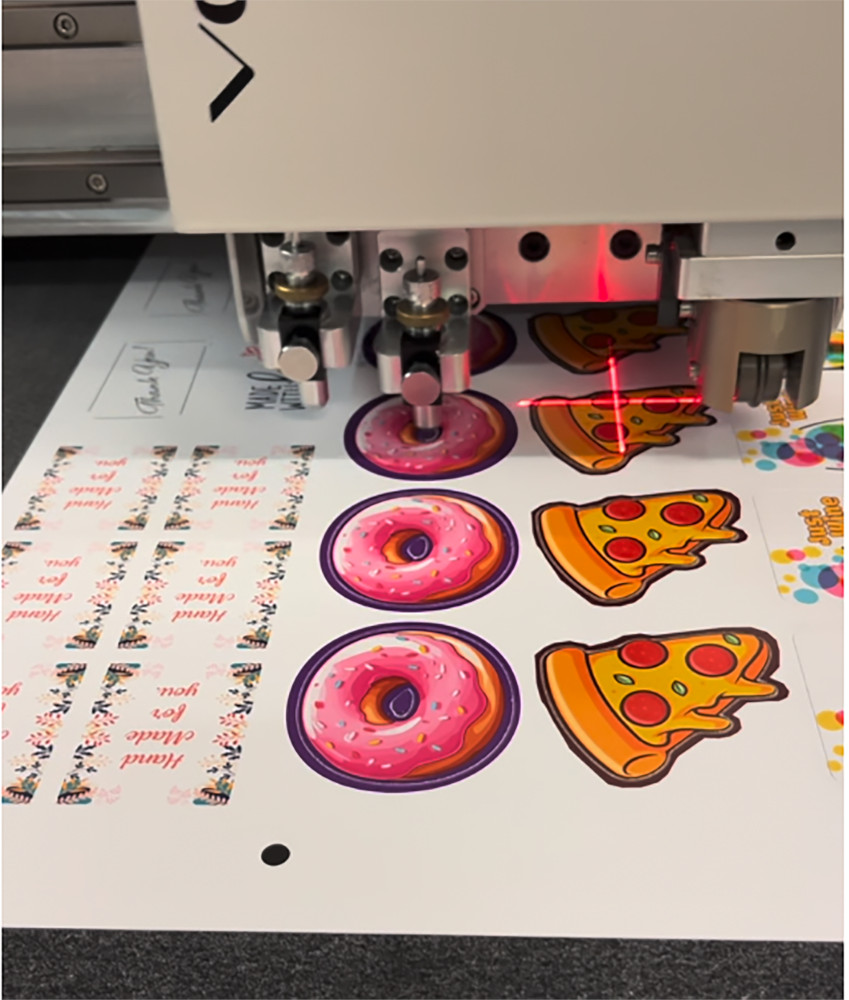

The machine uses sensor cameras to identify if it’s cutting in the right area.

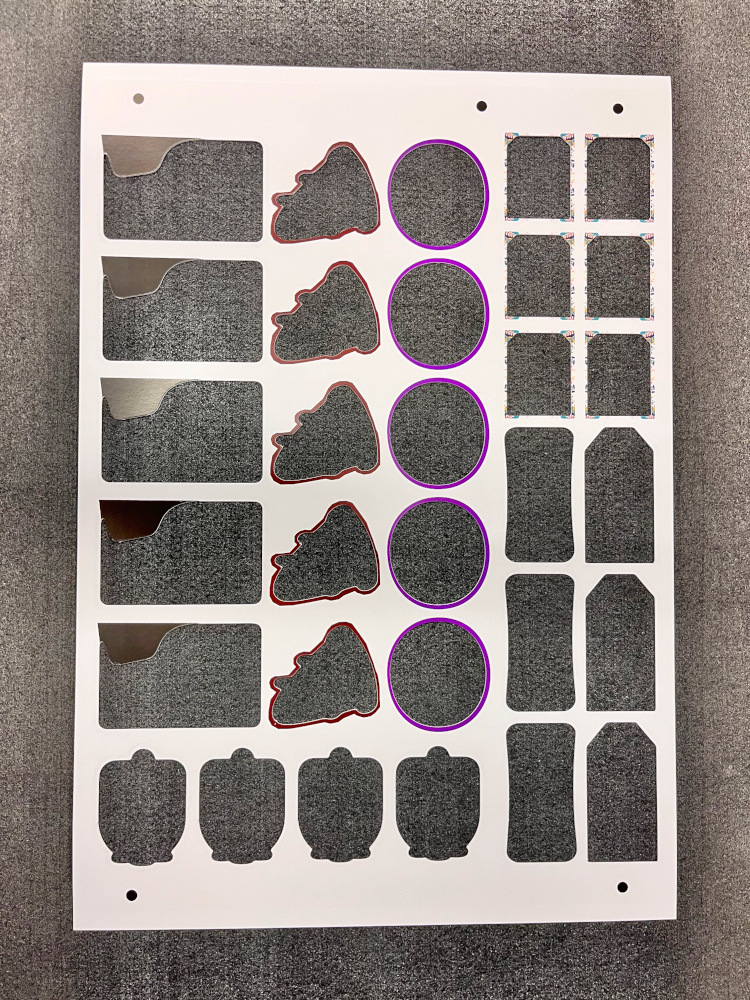

Kiss cutting

Kiss cutting involves slicing through the top layers of a material while leaving the underlying layer uncut. The term “kiss” denotes the gentle contact of the blade with the upper surface, creating a pattern or incision with just enough force to make an impression without penetrating the lower layer.

The majority of the work for CAD Cutting is done in the preparation. Target marks are added to make sure the CAD Cutter picks up the correct alignment of your substrate. The motion camera attached to the blade will use these targets as a guide for precision cutting.

Once all these marks have been identified and the material is ready to cut, a powerful vacuum built into the flatbed will suck the material down firmly and securely on the bed.

Suitable for one-off and short print runs.

See also Die Cutting

Can't see what you're looking for?

Our website lists our most popular products and configurations, but we can also print anything you can imagine.

Get in contact for a bespoke quote or advice on what techniques will make the most of your artwork.